Kanban in commodities software drives digital transformation

Human-driven digital transformation

I have a lot of tools in my garage. I bought a whole bunch of expensive Japanese carpentry saws so that I could get into Japanese carpentry. If you look in my backyard, you will find a garden but not much else. Subsequently, I am no longer allowed on Pinterest. The saws sit in the tool bench neatly arranged and full of potential.

I have personal AWS and Azure accounts. I go into these accounts and I see a mind-boggling amount of tools that I can use to build stuff. I play with a lot of them but I am barely scratching the surface. So much potential in these tools. If only the human had more time and resources to build something.

Most people leave out the human stuff and focus on the technology stuff. Digital transformation only works if you bring in the humans. Just ask the guys selling emerging technologies. Out of the following three factors, which matter most in digital transformation?

Organization?

People?

Tools?

Answer: All of the above.

Modifying the segregated conveyor belt

Segregation of duties is important to minimize operational risk in commodity trading. However, we have gone way are stifling innovation in the way that we have gone about it. Each person has a job. They do that job. They know the inputs and they know the outputs. They can prescribe efficiencies within the confines of their role.

In a commodity trading operation, everyone has personal tasks that they execute on an hourly, daily, weekly, monthly, and annual schedule.

I need to make sure all the prices are loaded by 7 pm.

I need to make sure the confirmations are sent out by the end of the day.

I need to send out my weekly status report.

I need to make sure that all actual quantities are captured and reconciled by the end of the month.

This deadline type of thinking is good for running a trading transaction conveyor belt.

Now let’s apply this type of thinking to digital transformation.

I need to implement machine learning by 7 pm.

I need to create a blockchain by the end of this week.

I need to set the drones free at the end of each month.

By the end of the year, I need to disrupt the industry.

Why the operational level matters to digital transformation

Digital Transformation is the process of creating effective teams that leverage advanced technologies to reinvent products and services from design and engineering to manufacturing and support, accelerating operational efficiency, and enterprise-wide growth.

You don’t get this executed at the strategic level. You need the operational level involved in the conceptualization, design, and execution phase.

But they are so locked in their ways…

No one said it was easy. This is a big reason why most digital transformation projects and software implementations fail or deliver meager results. The operational folks that keep the lights on are too busy…keeping the lights on. Innovation is fun until everyone is sitting in the dark.

In 2004, I came up with a stock options trading idea. The price of the stock went up exactly as I predicted. I just didn’t press the SELL button. Strategically, tactically I was ready to go. Operationally, I let a bunch of call options expire worthless because I was too busy doing my day job that actually paid the bills. Nothing like sitting in a design session while your options crater. Back in 2004, there was no app for that.

Start with the humans

Purchasing/trialing an emerging technology for an organization that is segregated by business functions and follow linear processes is a useless endeavor.

To help innovation while managing risk, we need to move from linear to agile without introducing operation chaos.

How?

Implement Kanban into the business.

Why Kanban?

It is the least disruptive Agile method to a business operation. It can layer onto your existing workflows. From Kanban, you can go anywhere but to organizationally prep your business to be able to adapt to a digital transformation lifestyle start with Kanban.

Kanban is Japanese for “visual sign” or “card.” It is a visual framework used to implement Agile that shows what to produce, when to produce it, and how much to produce. It encourages small, incremental changes to your current system and does not require a certain setup or procedure (meaning, you could overlay Kanban on top of other existing workflows).

Kanban was inspired by the Toyota production system and Lean Manufacturing. In the 1940s, Toyota improved its engineering process by modeling it after how supermarkets stock shelves. Engineer Taiichi Ohno noticed that supermarkets stock just enough product to meet demand, optimizing the flow between the supermarket and customer. Inventory would only be restocked when there was empty space on the shelf (a visual cue). And because inventory matched consumption, the supermarket improved efficiency in inventory management.

SIGN UP for the IGNITE Blog to receive more content like this.

How does Kanban prep for digital transformation?

Kanban allows you to execute your options at the operational level so that your technology initiatives do not expire worthlessly.

At Toyota, different teams would create a card (or Kanban) to communicate that they had extra capacity and were ready to pull more materials. Because all requests for parts were pulled from the order, Kanban is sometimes called the “pull system.”

These same ideas apply to managing business processes and digital transformation initiatives. In this context, development work-in-progress (WIP) takes the place of tasks, and new work can only be added when there is an “empty space” on the team’s visual Kanban board. Kanban matches the amount of WIP to the team’s capacity, improving flexibility, transparency, and output.

The digital transformation can be conceptualized, planned, and broken down by the strategic, tactical, and operational design sessions and then integrated into the Kanban system.

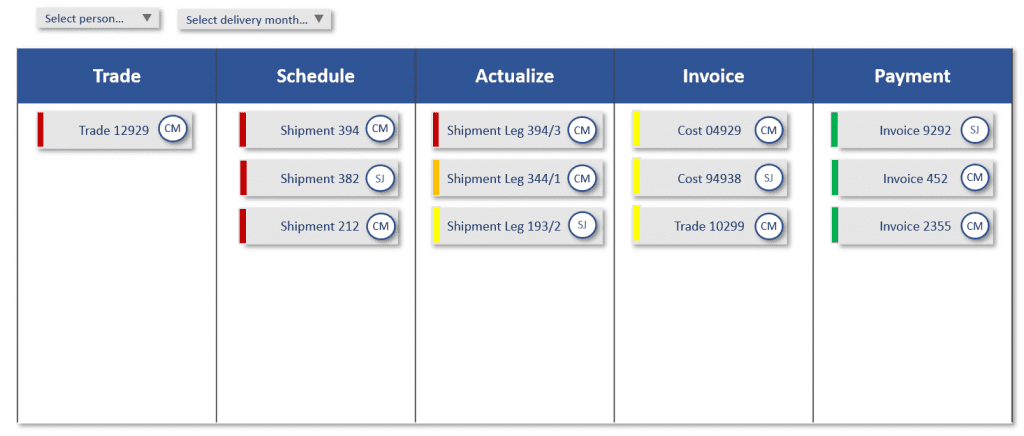

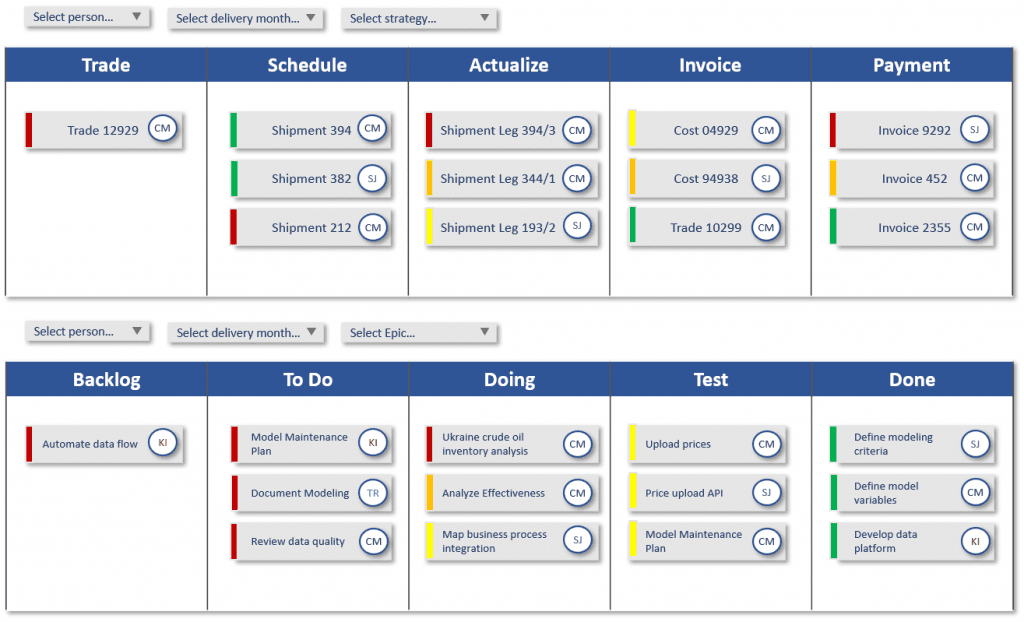

At IGNITE, we’ve incorporated Kanban into our cloud software because we understand the positive, transformational ways it can impact trading operations. It has proven to be a very effective method for bringing efficiencies to the trading floor. It is also proving to be very effective in helping operations folks manage multiple sets of workloads.

- CM might have too much on his plate.

- What is wrong with trade 12929?

- Should we switch some of CM‘s project tasks to SJ?

The great thing about this is that the operational person is no longer working from an inaccessible project plan and their personal job tracking spreadsheet. They don’t need to walk into their supervisor’s office and explain why something fell through the cracks. Everyone should see things falling through the cracks and apply preventative measures ( i.e. move deadlines or reassign tasks).

REQUEST A DEMO of IGNITE’s Kanban functionality to learn more about how it can help your trading business.

About the Author

Chris has 25 years of experience providing commodity trading and supply chain management software solutions to the Global Fortune 500. His area of expertise resides in identifying and maximizing the value of emerging technologies to increase profits while minimizing risk.